Comprehensive Tahoe Instrument Cluster Repair Solutions: Expert Gauge Fixes

Comprehensive Tahoe Instrument Cluster Repair Solutions: Expert Gauge Fixes

Blog Article

Discover Top Techniques for Efficient Automobile Tool Collection Fixing and Upkeep

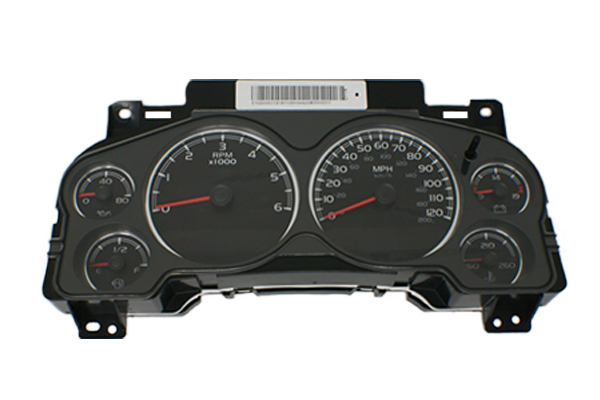

In the realm of automobile upkeep, the detailed system of an instrument collection plays an important function in supplying vehicle drivers with vital info about their car's performance. When faced with problems associated with this crucial part, having a detailed understanding of efficient repair work and upkeep methods is extremely important. From identifying common cluster breakdowns to utilizing specialized tools for precision repairs, a systematic approach can make sure optimum performance and long life of this vital control panel feature. Stay tuned to discover the top approaches that can improve the process of auto tool cluster fixing and upkeep, ultimately improving your driving experience and automobile efficiency.

Usual Tool Cluster Issues

Some common concerns might arise with lorry instrument collections, impacting their performance and accuracy. One widespread problem is a malfunctioning speedometer, which can cause safety concerns and potential legal issues if not addressed quickly. This issue typically stems from a faulty rate sensor or harmed electrical wiring, triggering unreliable speed readings or total failure of the speedometer. Another constant concern is a non-responsive gas scale, resulting in uncertainty regarding gas degrees and possible unanticipated break downs. This problem can be triggered by a malfunctioning gas degree sensing unit or a malfunctioning gauge collection. Additionally, flickering or dark control panel lights prevail issues among car proprietors. This problem may be credited to loose connections, a stopping working dimmer switch, or damaged bulbs. These problems can prevent the driver's ability to check crucial automobile details, stressing the significance of timely instrument cluster repair service and maintenance to guarantee optimal capability and precision while driving.

Vital Devices for Repair

When resolving usual instrument cluster problems such as malfunctioning speedometers, unresponsive gas assesses, or dim dashboard lights, having the essential tools for repair is crucial in ensuring effective and precise diagnostics and maintenance. Amongst the key devices required for auto instrument collection repair are an electronic multimeter for testing voltage and resistance degrees, a blowpipe for repairing faulty elements or loosened links, and a set of screwdrivers for disassembling the collection. Furthermore, specialized devices like collection removal hooks might be necessary for safely separating the collection from the control panel.

Analysis Methods for Fixing

Utilizing sophisticated analysis techniques is vital in efficiently troubleshooting issues within vehicle tool collections to determine and deal with underlying troubles properly. When confronted with a malfunctioning tool cluster, technicians usually count on diagnostic devices like multimeters, check devices, and specialized software to recognize the source of the problem. These tools make it possible for service technicians to access the cluster's interior systems, fetch error codes, and perform system tests to detect concerns efficiently. Additionally, strategies such as circuit screening, voltage checks, and signal evaluation play an important role in detecting complicated electronic mistakes within the instrument cluster. By adhering to methodical diagnostic procedures and analyzing diagnostic results accurately, professionals can enhance the troubleshooting process and make certain the correct performance of the instrument cluster. Regular training and remaining upgraded on the most up to date diagnostic innovations are crucial for technicians to properly troubleshoot contemporary tool clusters with advanced features. A comprehensive analysis method not just saves time but additionally advertises precision in fixing you could check here and determining tool cluster issues promptly.

Cleansing and Maintenance Tips

Software Updates and Calibration

Calibration is another vital aspect of preserving your auto tool cluster. This procedure entails adjusting the settings and criteria within the software program to make certain that the presented info, such as speed, fuel degree, and temperature level, is accurate and reputable. Proper calibration not only boosts the user experience but also adds to safety and security on the roadway by providing drivers with precise and trustworthy data.

To guarantee that your automobile tool cluster functions ideally, it is recommended to comply with the manufacturer's standards concerning software program updates and calibration periods. By staying positive in these areas, you can optimize the effectiveness and life expectancy of your tool collection.

Conclusion

Finally, efficient vehicle instrument cluster repair work and maintenance need a complete understanding of usual problems, necessary devices, diagnostic methods, cleaning up click now techniques, and software application updates. By using these techniques, specialists can efficiently repair and solve tool collection problems, making certain trustworthy and precise performance of the vehicle's control panel display screen. Normal upkeep and calibration are essential to stop future problems and guaranteeing the proper performance of the instrument collection.

When addressing usual instrument collection issues such as malfunctioning speedometers, less competent gas assesses, or dim control panel lights, having the important devices for repair work is critical in guaranteeing exact and effective diagnostics and upkeep. Amongst the primary devices needed for car tool collection repair work are an electronic multimeter for screening voltage and resistance levels, a soldering iron for dealing with damaged components or loosened connections, and a collection of screwdrivers for taking apart the collection. Furthermore, specialized tools like cluster removal hooks may be needed for securely detaching the collection from the dashboard.

In final thought, effective auto tool collection fixing and maintenance need blog here a detailed understanding of common issues, necessary tools, diagnostic techniques, cleaning up techniques, and software application updates. Normal upkeep and calibration are vital to preventing future issues and guaranteeing the proper performance of the tool collection.

Report this page